Arc flash is a sudden, explosive release of energy from an...

ReadArc flash is a sudden, explosive release of energy from an electrical fault. It can cause severe burns, fires, and even death. While electrical systems may appear safe, hidden problems can increase the risk of arc flash. This article explores the dangers of arc flash and how to protect the power system under your responsibility, by following safety standards and performing thorough arc flash hazard analysis.

What is arc flash?

An arc flash is a sudden, explosive release of energy resulting from a short circuit within an electrical power system, typically within oil and gas, industrial, or commercial settings. It occurs when electrical current deviates from its intended path, typically due to insulation breakdown, equipment failure, or human error. The intense electrical discharge ionizes the surrounding air, creating an electrical arc that releases energy in the form of heat, pressure waves, and light.

During an arc flash event, energy is no longer confined to its electrical state. Instead, it converts into other forms that can be extremely destructive and hazardous:

- Heat: Temperatures during an arc flash can reach up to 35,000°F (19,427°C), hotter than the surface of the sun. This intense heat can instantly ignite or melt nearby materials, causing severe burns or fires. Vaporized metals can be inhaled by individuals in the vicinity, producing internal lung burns.

- Pressure waves: The rapid expansion of gases and superheating of the air create a powerful blast, specifically referred to as ‘arc blast’. This blast can shatter equipment, propel debris at high speeds, and cause structural damage.

- Light: The brilliant flash of light emitted can cause temporary or permanent blindness if viewed directly.

The severity of an arc flash depends on several factors, including the fault current, system voltage, and the duration of the arc. Even at lower energy levels, an arc flash can be life-threatening to anyone in its vicinity and result in significant property damage. At higher energy levels, it poses an even greater risk, potentially leading to catastrophic outcomes such as fatalities or large-scale equipment failure.

Although it is difficult to determine the actual number of arc flash events per year in the United States, some sources indicate there are around 2,700 instances per year [1], while others refer to as many as 30,000, with 7,000 burns, 2,000 hospitalizations and 400 deaths [2].

What is the regulatory framework around arc flash?

In the United States, the regulatory framework governing electrical safety in the workplace, including arc flash hazards, is centered around the “Standard for Electrical Safety in the Workplace” developed by the National Fire Protection Association (NFPA 70E). This standard provides comprehensive definitions, guidelines, requirements, and expectations to identify electrical hazards, assess associated risks, and implement mitigation strategies. Its ultimate goal is to ensure that workers interact with electrical systems safely, minimizing exposure to hazards such as arc flash.

The Role of NFPA 70E and OSHA

Although NFPA 70E is neither a law nor incorporated by reference into legislation, it is widely and voluntarily adopted by employers across industries. Its prescriptive requirements serve as a practical means for companies to comply with the performance safety requirements enforced by the Occupational Safety and Health Administration (OSHA), a federal agency under the U.S. Department of Labor. OSHA’s regulations provide general workplace safety rules, while NFPA 70E offers detailed, actionable measures to meet such requirements.

Compliance with NFPA 70E is not proactively monitored but often comes under scrutiny following workplace incidents. Additionally, local and state regulations may impose supplementary requirements, but NFPA 70E remains the dominant reference standard nationwide.

NFPA 70E’s Focus on Hazard Elimination and Safe Work Conditions

The primary emphasis of NFPA 70E is on eliminating electrical hazards entirely or, when that is not feasible, establishing electrically safe work conditions. For scenarios where risks like arc flash cannot be fully eradicated, NFPA 70E provides methods to quantify hazards and prescribes measures for mitigation.

Specifically regarding arc flash hazards, NFPA-70E describes two methodologies for determining a safe ‘boundary’ from a given arc flash source (also known as the “arc flash boundary”), as well as the personal protective equipment (PPE) should workers need to cross such boundary while handling electrical equipment in other than normal operations:

- Incident Energy Analysis Method: This approach involves detailed calculations to determine the amount of thermal energy that could be released during an arc flash event.

- PPE Category Method: This simpler method uses predefined tables to estimate the required PPE based on system voltage, fault current, and other parameters.

Incident Energy Analysis and IEEE 1584

On the incident energy analysis method, table D.1 in NFPA-70E 2024 outlines the limitations and parameters of a few approaches, by different authors, to calculate incident energy. Although there are no expectations to use a specific or given method, the one provided by the ‘Guide for Performing Arc-Flash Hazard Calculations’, developed by the Institute of Electrical and Electronics Engineers, better known as IEEE-1584, is the most widely adopted for calculating incident energy, considering variables such as bolted short circuit, enclosure dimensions, and system voltage.

The IEEE-1584 standard explicitly requires ‘qualified persons’, defined as those with experience in power system studies and arc flash hazard analysis by means of skills and knowledge, to be the ones performing arc flash calculations. NFPA 70E, on the other hand, requires that arc flash quantification via the incident energy analysis method must be updated every 5 years, or when changes in the electrical system occur, whichever happens first.

State-Level Regulations and Licensing Requirements

At the State Level, Engineering Practice Laws impose specific requirements on professionals performing arc flash analyses. State Engineering Boards mandate and enforce that such activities be conducted only by licensed professional engineers (PEs). The mere act of offering arc flash calculation services without the proper licensure—whether as an individual or a company—constitutes a violation of state laws and can result in legal prosecution.

How is arc flash calculated?

Arc flash quantification, as outlined in IEEE 1584, requires a methodical approach and the application of a sophisticated algorithm. To ensure legal compliance and accurate results, it is imperative that these analyses are performed by individuals or companies with the appropriate skills, experience, and tools, as well as the qualifications mandated by law. Proper licensing and expertise are critical not only to meet regulatory requirements but also to uphold safety and reliability in arc flash mitigation.

The data collection stage

The process begins with a comprehensive data collection phase, which involves gathering information about the electrical system in question. This includes single-line diagrams, dimensional drawings of enclosures, and datasheets and settings of protective devices. Ideally, this data should be supplemented with field measurements, annotations, and photographs captured during a detailed survey of the site.

Additionally, it is essential to consider the system’s operational modes, the type of loads it supports, and its proximity to generation sources, as these factors significantly influence the arc flash risk. Following data collection, a short circuit study is conducted in accordance with the IEEE 551 standard, the “Recommended Practice for Calculating Short-Circuit Currents in Industrial and Commercial Power Systems.” This analysis may optionally be complemented by a protection coordination study, guided by IEEE 242, the “Recommended Practice for Protection and Coordination of Industrial and Commercial Power Systems”, which is highly advised.

Finally, for each motor control center (MCC), switchboard, panel, and enclosure where arc flash figures are required, the next step is to collect physical characteristics specific to the equipment. This includes gathering data on dimensions and gaps between conductive parts. Additionally, electrode configurations and working distances must be decided, based on the guidelines provided in IEEE 1584.

The analysis stage

A series of step-by-step calculations is performed to determine key parameters such as arcing currents, incident energy, and arc flash boundaries for each point of interest in the system. These calculations involve complex equations that vary depending on system voltage and equipment configurations. The equations are detailed and incorporate numerous constants, correction factors, and assumptions, which depend on variables like voltage level and electrode configuration.

The process also requires the incorporation of time-current characteristics from protective devices. The resulting trip times, combined with the arcing current values, yield the definitive calculations for arc flash boundaries and incident energy levels. These values are used to establish safe working distances and determine the appropriate level of personal protective equipment (PPE) required to ensure worker safety.

The application of the IEEE 1584 calculation approach requires significant engineering judgment to make critical decisions. For example, determining which type of short circuit case (three-phase, line-to-line, or line-to-ground) would yield the most conservative arc flash results at each point of interest is essential. It is not always intuitive that higher short-circuit currents result in greater arc flash energy, as arc flash energy depends on a combination of current magnitude and protective device trip time. In many cases, lower fault currents can lead to longer trip times, potentially increasing the energy released during an arc flash. Comparing results for multiple fault scenarios and selecting the most conservative one is common. However, because the IEEE 1584 methodology was developed for three-phase faults only, applying it to other fault types may produce overly conservative results that require further interpretation.

The nuances of arc flash quantification

Additional factors can further complicate arc flash calculations. For instance, special protective devices, such as current-limiting fuses, can significantly decrease the arcing current that otherwise would have occurred without the presence of such fuses, consequently altering the incident energy. Other considerations include system grounding methods, ground impedance, and the presence of equipment such as remote circuit breaker racking devices, in-premises generators, or large motors. These variables not only affect the complexity of the calculations but also influence the final arc flash results, requiring a careful consideration of impacts.

Leveraging Simulation Software with Engineering Expertise

In practice, most arc flash calculations are performed using commercial power system simulation software such as ETAP, SKM, and EasyPower. These tools automate much of the calculation process and even generate arc flash labels directly, saving substantial time and effort compared to manual calculations. However, reliance on these tools does not replace the need for a qualified engineer with a thorough understanding of arc flash principles, standards, and system behavior. The engineer remains legally responsible for the accuracy and reliability of the results. In the event of an arc flash incident or legal litigation, the liability ultimately rests with the engineer in charge, underscoring the critical importance of technical expertise and diligence. A knowledgeable engineer ensures that the software is used appropriately, validates results against expected outcomes, and applies engineering judgment to address any anomalies. Simply relying on the convenience of automation without understanding the principles behind the calculations compromises both safety and compliance.

The deceptive threat of arc flash

One of the challenges with arc flash lies in its deceptive nature: much like losing the brakes in a car that never gets maintained, the certainty of a problem often only becomes apparent during a catastrophic event. Electrical systems can appear to operate normally despite underlying vulnerabilities, such as improper maintenance, aging equipment, or unnoticed design flaws, that increase the likelihood of an arc flash. These hidden risks remain dormant until triggered by a fault, such as a dropped tool, insulation failure, or human error, often with devastating consequences. This unpredictability underscores the urgent need for proactive measures, including regular system audits, and thorough arc flash hazard analysis updates. Waiting for an arc flash event to confirm the existence of a problem is not only dangerous but can result in severe injuries, fatalities, significant property damage, or legal litigation. Recognizing and addressing these latent threats before they manifest is critical to ensuring workplace safety and electrical system reliability.

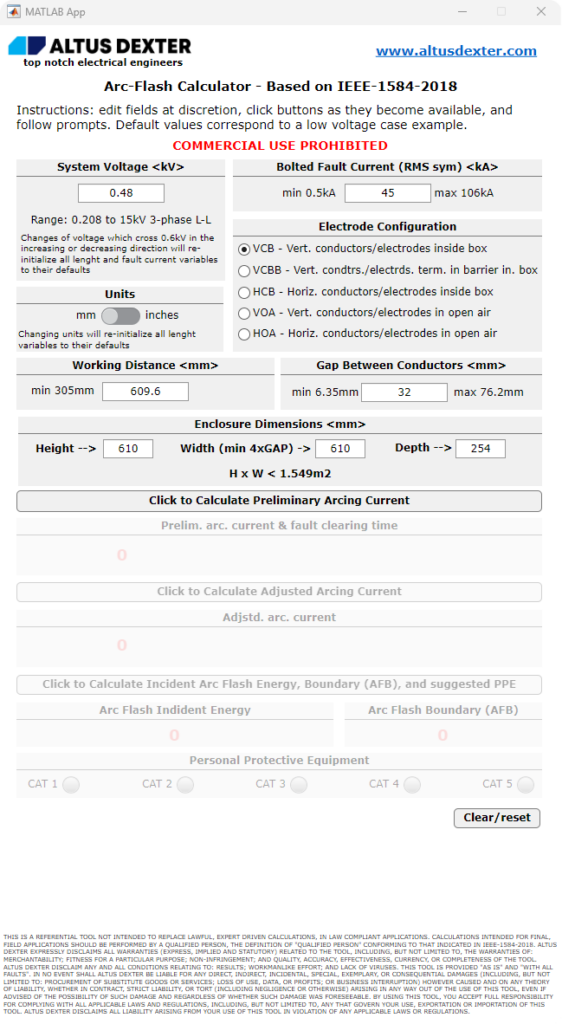

Explore Altus Dexter’s Arc Flash Tool

We offer an Arc Flash Tool on our website that allows you to rapidly self-assess arc flash numbers without the expense of a power system simulation license or the time-consuming process of manual IEEE-1584 calculations. It is completely free, only requiring a run-time file download, and no submission of information.

Key takeaways

Arc flash is an often-overlooked yet profoundly hazardous phenomenon that can result in catastrophic consequences for both people and property. It demands diligent attention, adherence to established safety standards like NFPA 70E, and the use of rigorous calculation methodologies such as those in IEEE 1584. While advanced software tools simplify the computational process, their effectiveness is only as reliable as the engineer applying them. Proactive measures such as regular audits, and thorough arc flash hazard analysis updates are crucial to identifying hidden risks before they manifest. Ultimately, the prevention of arc flash incidents depends on a blend of technical expertise, sound engineering judgment, and a commitment to fostering a culture of workplace safety.

References

[1] National Fire Protection Association. (2024, May 1). What is arc flash and how can you stay safer. Retrieved from https://www.nfpa.org/news-blogs-and-articles/blogs/2024/05/01/what-is-arc-flash-and-how-can-you-stay-safer

[2] O’Connor, T. (2022, July 15). The dangers of arc flash: Know the risks and how to protect yourself. Electrical Contractor Magazine. Retrieved from https://www.ecmag.com/magazine/articles/article-detail/the-dangers-of-arc-flash-know-the-risks-and-how-to-protect-yourself

[3] IEEE 1584-2018 – IEEE Guide for Performing Arc-Flash Hazard Calculations. New York, NY: Institute of Electrical and Electronics Engineers, 2018. https://standards.ieee.org/standard/1584-2018.html

[4] National Fire Protection Association. NFPA 70E: Standard for Electrical Safety in the Workplace. 2024 edition. Quincy, MA: National Fire Protection Association, 2023. https://www.nfpa.org/codes-and-standards/nfpa-70e-standard-development/70e

Recommended citation.

Pineda, F., “Arc Flash, the Deceptive Threat”. Website article (2024). Altus Dexter. www.altusdexter.com

About the author

Fabian Pineda, P.E., is the Founder and Managing Director of Altus Dexter. He has extensive experience in project management, design, operation, reliability, and maintenance of electrical systems for industrial, oil, gas and offshore applications.

We also recommend

Electrical Reliability in Oil and Gas: A Study Case

In the high-stakes environment of oil and gas, electrical system reliability...

ReadCONTACT US

- (832) 773-1194

- info@altusdexter.com